Key features

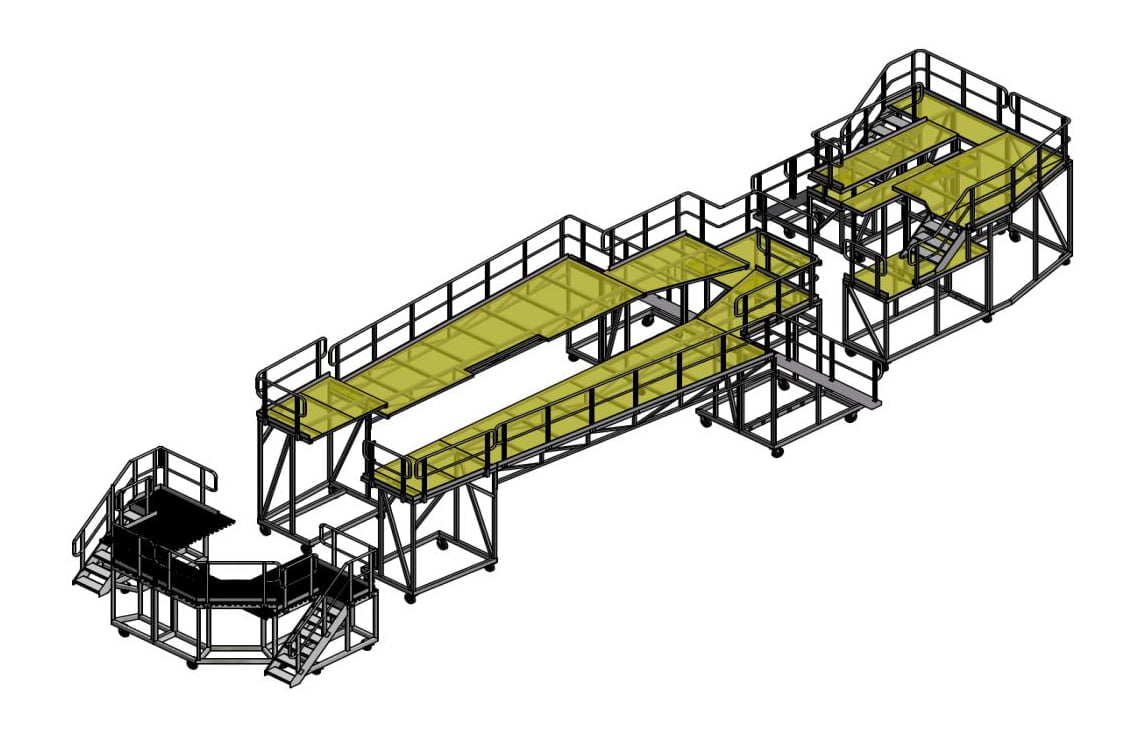

- Antiskid surface and rubber fender protection

- Heavy duty wheels with brakes

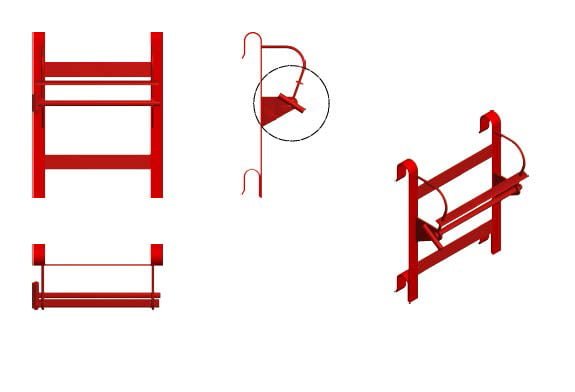

Swivel wheels with brakes, 600kg load per wheel. - Removable / telescope railing

In some places, it is required to be able to lower the railing. - Electrical, lights & pneumatic installation

- Maintenance docking system design and load rating

Design for 200 kg/m2

Click for a larger image

Maintenance docking system

| Part Name | Maintenance docking system |

| Part Number |

Consist of:

|

| AMM Reference | N/A |

Click for a larger image

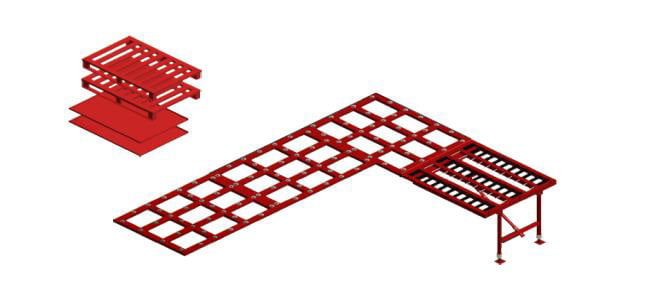

Line maintenance docking system

| Part Name | Line maintenance docking system |

|

Part Number RA-S92LD-1609-0 |

Consist of:

|

| AMM Reference | N/A |

This docking system supports line maintenance activities on the S-92. It is produced in lightweight aluminum and the floor have an antiskid surface. All edges against the fuselage have a rubber protection band to avoid any harm to the helicopter. There is a variety of accessories to choose from as described in this brochure.

Electrical, lights & pneumatic installation

This option has a single point electrical connection on each stand, connected to a numerous electrical connection around the stands. It gives the mechanic easy access to electrical power as they are working around the helicopter. It adds lighting under both side stands and railing to improve the working conditions for the mechanic. The customer may choose from 220V or 110V Installation.

Docking system accessories

Surface treatment

All ground support accessories are powder coated red to give durability and a nice finish.

| Part Name | Pneumatic installation |

| Part Number | RA-S92DSA- 1854-0 |

| AMM Reference | N/A |

Pneumatic installation

This option has a single point pneumatic connection on each stand, connected to a numerous pneumatic connection around the stands. It gives the mechanic easy access to air as they are working around the helicopter.

Electrical installation

| Part Name | Electrical installation |

| Part Number | RA-S92DSA- 1857-0 (220 V) |

| AMM Reference | N/A |

This option has a single point electrical connection on each stand, connected to a numerous electrical connections around the stands. It gives the mechanic easy access to electrical power as they are working around the helicopter. It adds lighting under both side stands to improve the working conditions.

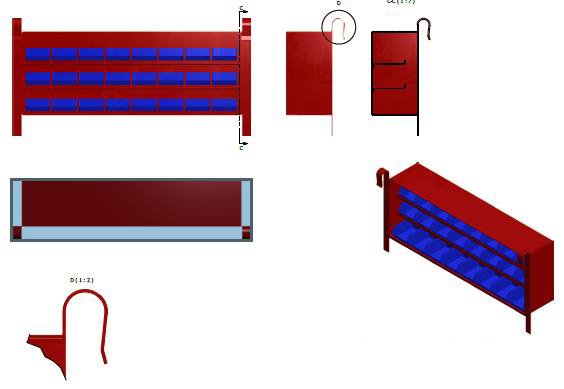

Tail platform fairing interior

| Part Name | Tail platforms fairing interior |

| Part Number | RA-S92DSA- 1989-0 |

| AMM Reference | N/A |

The tail stand fairing interior is designed to utilize the space under (inside) the tail stand. It

has shelves for numerous fairings, cargo compartment linings, tail rotor components, main

rotor components and more.

Note: S-92 on picture, same principle for CH 53K

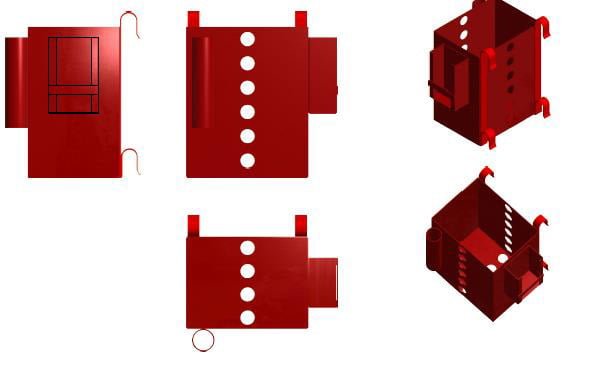

Storage cabinet

| Part Name | Storage cabinet |

| Part Number | RA-DSA- 1990-0 |

| AMM Reference | N/A |

The storage cabinets are designed to hold fairing screws, removed component etc. They

slide over the side rails and can be positioned where most suitable. It is up to each operator to determine how many needed and how to utilize them. The recommendation is one on each side stand and one on the tail stand, three altogether.

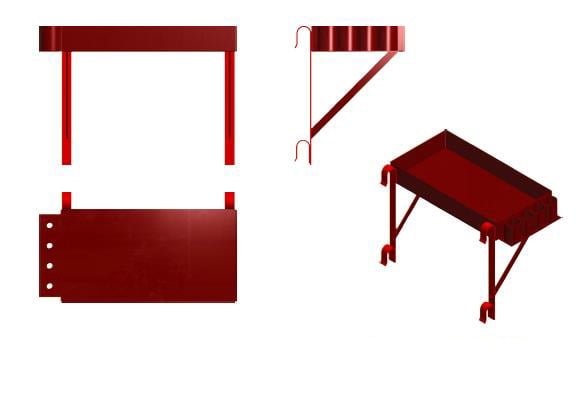

Working table

| Part Name | Working table |

| Part Number | RA-DSA- 1987-WT-0 |

| AMM Reference | N/A |

The working tables are designed to hold tools, removed component etc. They slide over the

side rails and may be position where most suitable. It is up to each operator to determine how many needed and how to utilize them. The recommendation is one on each side stand and one on the tail stand, three altogether.

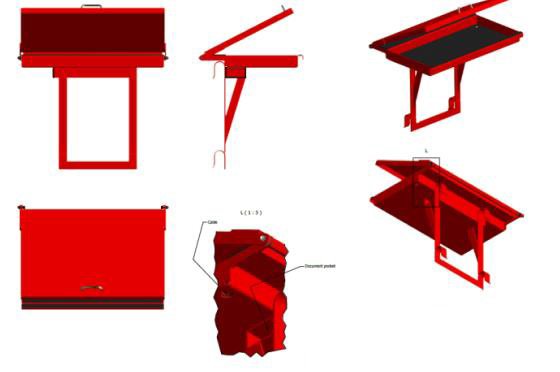

PC table

| Part Name | PC table |

| Part Number | RA-DSA- 1816-0PC |

| AMM Reference | N/A |

The PC tables are designed support a PC for the mechanic during his work. They slide over

the side rails and may be positioned where most suitable. It is up to each operator to determine how many needed and how to utilize them. The recommendation is one on each side stand and one on the tail stand, three altogether.

Paper dispenser

| Part Name | Paper dispenser Holder |

| Part Number | RA-DSA- 1852-PD-0 |

| AMM Reference | N/A |

The paper dispenser is designed to support paper rolls. They slide over the side rails and

may be positioned where most suitable. It is up to each operator to determine how many needed and how to utilize them. The recommendation is one on each side stand and one on the tail stand, three altogether.

Container for cleaning rags

| Part Name | Container for cleaning rags |

| Part Number | RA-DSA- 1991-0 |

| AMM Reference | N/A |

The container for rags is designed to support paper rolls. They slide over the side rails and

may be position where most suitable. It is up to each operator to determine how many needed and how to utilize them. The recommendation is one on each side stand and one on the tail stand, three altogether

S-92 Ground Support Equipment

General description:

Accessories are usable for maintenance and line maintenance docking system.

Surface treatment

All ground support accessories are powder coated red to give durability and a nice finish.

Certificate

All equipment as slings etc., will be delivered with a certificate.

ATA 9 Towing

S-92 Tow bar

| Part Name | Tow bar |

| Part Number RA-S92GSE- 1581-0 RA-S92GSE- 1581-1 |

Tow Bar, Remote release, shear pin and damper function Tow Bar, shear pin and damper function |

| AMM Reference | 09-00-00 |

Tow bar for moving the helicopter on ground.

ATA 10 Parking and Mooring

MGB/Engine/ Top deck area cover

| Part Name | S-92 MGB-Engine -Top deck area cover |

| Part Number | RA-GSE- 101005-S92 MGB Cover |

| AMM Reference | 10-10-05 |

This cover is designed to protect the complete top deck area against rain, snow and sand

when the helicopter is parked outside.

ATA 25 Equipment furnishing

Cabin cargo loading system

| Part Name | Cabin cargo loading system |

|

Part Number RA-S92GSE- 1885-0 |

Consist of: * 1 ea Hinged roller board with support legs * 2 ea Sliding board * 1 ea roller segments * 1 ea aluminum pallet |

| AMM Reference | 25-00-00 |

The cabin cargo loading system is designed to support loading of cabin cargo. It has a roller/ ball concept that makes it easy to load pallets/ baskets into the cabin. It is rated for loads up to 500 kg/ 1000 lbs.

ATA 25 Rescue Hoist Cable Wash Trolley

| Part Name | Rescue hoist cable wash trolley |

| Part Number | RA-GSE-2071-1-RHC |

The Rescue hoist-cable wash trolley is designed for safe and easy washing of rescue cable

after use. The trolley consists of a wash basin and a drum that reels the cable. The drum is equipped with adjustable braking system that ensures correct tension when

spooling the cable.

ATA 32 Main landing gear

Aft Floatation gear removal/ installation trolley

| Part Name | Aft floatation gear removal/installation trolley |

| Part Number | RA-S92GSE- 1896-0 |

| AMM Reference | 32-71-02 |

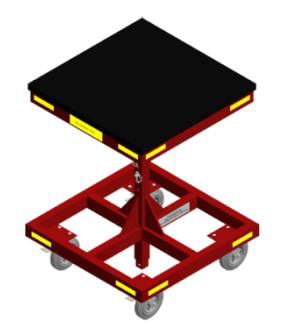

Aft floatation gear trolley is designed to support during removal/installation of the aft floatation gear. The top plate is hinged to adjust to the float, and the height of the tool can be adjusted by turning a screw jack wheel.

ATA 54 Nacelles/Pylon

Main rotor top fairing trolley

| Part Name | Main rotor top hat trolley |

| Part Number | RA-S92GSE- 1897-0 |

| AMM Reference | 54-23-01 |

The main rotor top fairing trolley is designed to support during removal of the top fairing

including the RIPS distributor/ slip ring.

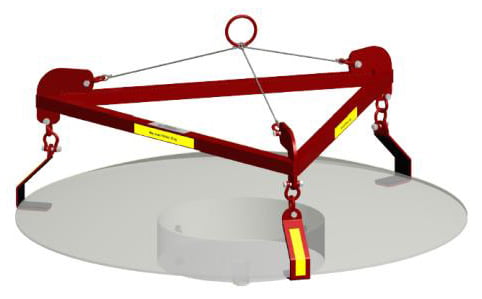

Main rotor head top fairing sling

| Part Name | Main rotor top hat sling |

| Part Number | RA-S92GSE- 1887-0 |

| AMM Reference | 54-23-01 |

The main rotor top fairing sling is designed to support during removal of the top fairing including the RIPS distributor/ slip ring.

Main rotor pylon forward sliding fairing sling

| Part Name | Main rotor pylon forward sliding fairing sling |

| Part Number | RA-S92GSE- 1886-0 |

| AMM Reference | 54-31-01 |

The main rotor sliding fairing sling is designed to support during removal/installation of the

fairing.

ATA 55 Stabilizer

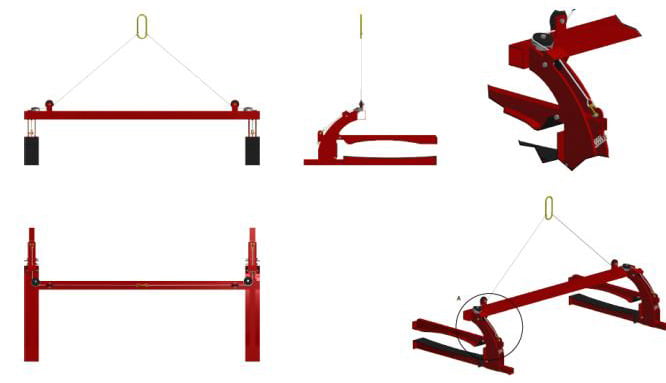

Horizontal stabilizer removal/installation trolley

| Part Name | Horizontal stabilizer removal/installation trolley |

| Part Number | RA-S92GSE- 1895-1 |

| AMM Reference | 55-11-01 |

The horizontal stabilizer trolley is designed to support during removal/installation of the stabilizer. The top plate is hinged to adjust to the stabilizer, and the height of the trolley can be adjusted by turning a screw jack wheel.

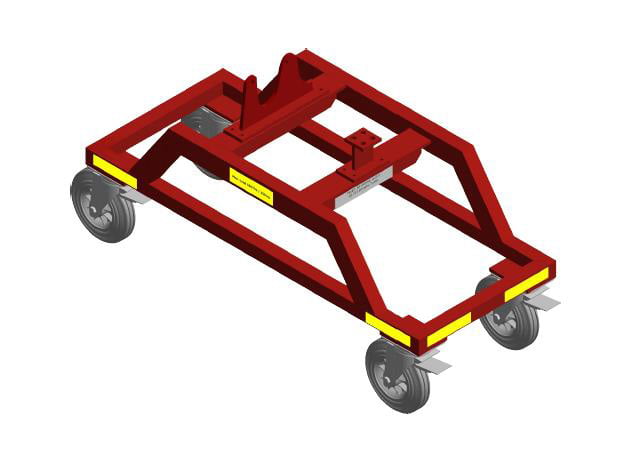

ATA 62 Main rotor

Main rotor blade trolley

| Part Name | Main rotor blade trolley |

| Part Number | RA-S92GSE- 1608-0 |

| AMM Reference | 62-10-01 |

The main rotor blade trolley is designed to support all four main rotor blades when they are removed from the helicopter.

Main rotor blade sling

| Part Name | Main rotor blade sling |

| Part Number | RA-S92GSE- 1618-2 |

| AMM Reference | 62-10-01 |

The main rotor blade sling is designed for removal/installation of main rotor blades. A clamp type sling will close automatically around the blades as the sling is hoisted up.

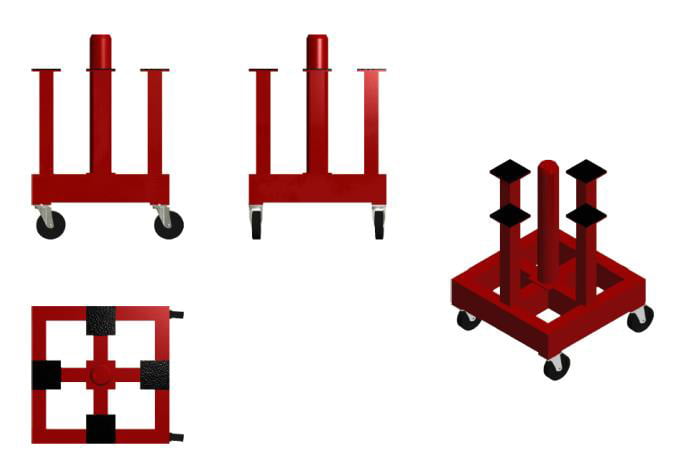

Main rotor hub

| Part Name | Main rotor hub stand |

| Part Number | RA-S92GSE- 1613-0 |

| AMM Reference | 62-21-00 |

The main rotor hub stand is designed to support the main rotor hub when it is removed from the helicopter.

Swash plate stand

| Part Name | Swash plate stand |

| Part Number | RA-S92GSE- 1888-0 |

| AMM Reference | 62-31-01 |

The swash plate stand is designed to support the swash plate when it is removed from the helicopter (with main servos and stationary scissor attached if applicable).

ATA 63 Main gear box

Main gear box / main rotor head assembly stand

| Part Name | Main gear box/ main rotor head assembly stand |

| Part Number | RA-S92GSE- 2158-0 |

| AMM Reference | 63-20-01 |

The main gear box stand is designed to support the MGB or a complete assembly with

modules and main rotor head when it is removed from the helicopter.

Main gear box/ main rotor head assembly work platform

| Part Name | Main gear box/ main rotor head assembly work platform |

| Part Number | RA-S92GSE- 2152-0 |

| AMM Reference | 63-20-01 |

The main gear box/ main rotor head assembly work platform is designed to support maintenance activity on the assembly when removed from the helicopter.

ATA 71 Engines

Engine stand

| Part Name | Engine stand |

| Part Number | RA-S92GSE- 1615-0 |

| AMM Reference | 71-00-00 |

The engine stand is designed to support the engine when it is removed from the helicopter.

Engine maintenance stand (adjustable height)

| Part Name | Engine maintenance stand (adjustable height) |

| Part Number | RA-S92GSE- 1988-0 |

| AMM Reference | 71-00-00 |

The engine stand is designed to support the engine when it is removed from the helicopter and when conduction maintenance on the engine. The height can be adjusted to ease the access and working conditions for the mechanic.

ATA 25 Rescue Hoist Trolley

| Part Name | Rescue Hoist Trolley |

| Part Number | RA-92GSE-2188-1 |

The Rescue Hoist trolley is designed to support safe storage of Dual Rescue Hoist when removed from Aircraft. The trolley uses the same attachment points as if hoist was installed on the AC. It also supports the rescue hoist if any off-aircraft maintenance or inspection is required. All structure is in aluminum which are powder coated red. It has 4ea individual wheels with brakes for easy movement and parking of the trolley.

ATA 62 Main Rotor Bifilar Trolley

| Part Name | Main Rotor Bifilar Trolley |

| Part Number | RA-92GSE-2091-1 |

The Main Rotor Bifilar trolley is designed to support safe storage of M.R.H Bifilar when removed from aircraft. It also supports the M.R. Bifilar if any off-aircraft maintenance or inspection is required. All structure is in aluminum which are powder coated red. There is rubber on the support surface for protection.

It has 4ea individual wheels with brakes for easy movement and parking of the trolley

ATA 64 Tail Rotor Blade Trolley

| Part Name | Tail Rotor Blade Trolley |

| Part Number | RA-S92GSE-2092-1 |

The Tail Rotor Blade trolley is designed to support safe storage of 4ea T.R. blades when removed from the aircraft. The trolley also supports the T.R. blades if any off-aircraft maintenance or inspection is required. All structure is in aluminum which is powder coated red. There is foam in all slots for protection of the blades.

It has 4ea individual wheels with brakes for easy movement and parking of the trolley.

ATA 71 CT7-8A Engine sling

| Part Name | CT7-8A Engine sling |

| Part Number | RA-92GSE-2178-1 |

The CT7-8A Engine is designed to support removal and installation of the Engine. It comes with CE -Marking and a load/lifting certificate. All structure is in aluminum which is powder coated red.